The Impact of 3D Printing on Manufacturing: A Personal Exploration

Diving into the 3D Printing Revolution

A Personal Encounter with 3D Printing Wonders

Embarking on a journey into the world of 3D printing felt like stepping into the future of manufacturing. Intrigued by the buzz surrounding this technology, I delved into the realm of additive manufacturing to unravel its profound impact on the industry.

Understanding the Basics of 3D Printing

Unveiling the Magic: How 3D Printing Works

From Filament to Form: Witnessing the Printing Process

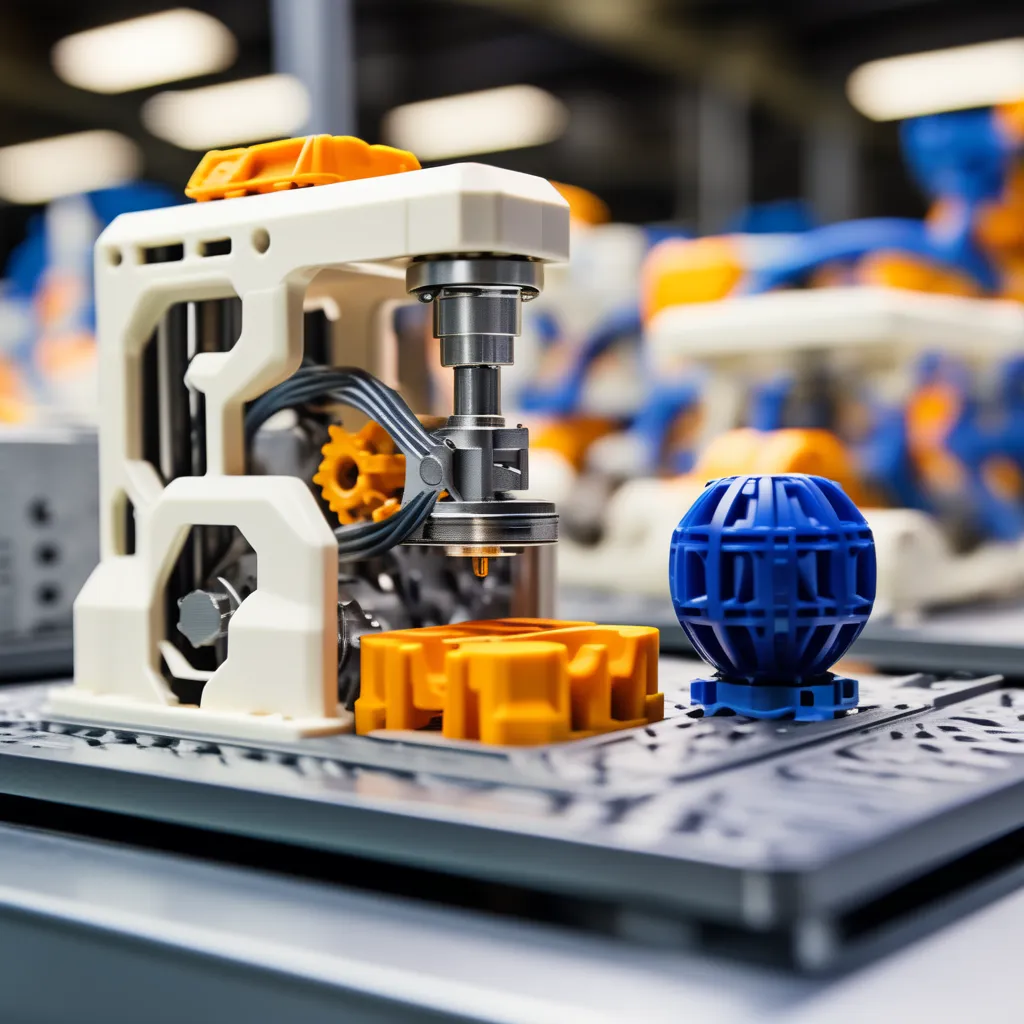

My initiation involved witnessing the mesmerizing process of turning raw filament into intricate, three-dimensional objects. The layer-by-layer construction, akin to watching a tangible idea materialize, left me in awe of the precision and creativity inherent in 3D printing.

The Power of Digital Blueprints: Designing in the Virtual Realm

Exploring the world of CAD (Computer-Aided Design) software allowed me to craft digital blueprints for my creations. The newfound ability to visualize and tweak designs on a screen before they materialized illustrated the efficiency and adaptability that 3D printing brings to the creative process.

Revolutionizing Prototyping and Production

Breaking the Mold: 3D Printing in Prototyping

Rapid Prototyping: A Game-Changer in Product Development

Traditional prototyping often involved lengthy processes, but 3D printing ushered in a new era of rapid prototyping. Personal anecdotes of iterating through design modifications in a matter of hours rather than weeks underscored the transformative impact on product development cycles.

Small Batch Production: Redefining manufacturing Dynamics

My exploration extended to small batch production, where 3D printing demonstrated its prowess in efficiently crafting limited quantities. The ability to produce intricate components without the need for expensive molds hinted at a shift in the traditional manufacturing paradigm.

From Aerospace to Healthcare: Widening Applications

Beyond Boundaries: 3D Printing Across Industries

Sky's the Limit: 3D Printing Takes Flight in Aerospace

Venturing into the aerospace industry, I discovered how 3D printing revolutionized the manufacturing of lightweight, complex components. The aerospace sector's ability to optimize designs for enhanced performance showcased the adaptability of 3D printing in high-stakes environments.

Medical Marvels: Personalized Healthcare Solutions

Exploring 3D printing applications in healthcare revealed a world of personalized solutions. Personal anecdotes of witnessing patient-specific implants and prosthetics being created emphasized the transformative potential of this technology in improving lives.

Overcoming Challenges and Shaping the Future

Navigating Challenges: The Evolution of 3D Printing

Material Limitations and Sustainability Concerns

While celebrating the advancements, it's crucial to acknowledge challenges. Material limitations and sustainability concerns surfaced, prompting the industry to innovate towards more eco-friendly materials and processes. My journey reflected the ongoing efforts to strike a balance between innovation and environmental responsibility.

The Future Unfolds: 3D Printing as a Catalyst for Change

In conclusion, my personal exploration of 3D printing showcased its transformative impact on manufacturing. From rapid prototyping to reshaping industries like aerospace and healthcare, the technology has proven its versatility. As we navigate challenges and witness continuous innovations, it's evident that 3D printing is more than a manufacturing technique—it's a catalyst for shaping the future of how we create and build.

No comments:

Post a Comment